MIM

What Is MIM?

Process Overview

When to Use MIM

General Guidelines

Technology Comparisons

Materials Range

Materials List

Design Guidelines

Designing for Manufacturability

Uniform Wall Thickness

Thickness Transition

Coring Holes

Draft

Ribs and Webs

Fillets and Radii

Threads

Holes and Slots

Undercuts

Gating

Parting Lines

Decorative Features

Sintering Support

Secondary Operations

Threads

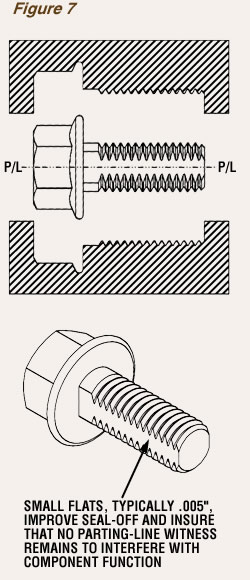

Both internal and external threads can be formed by MIM; however, tapping internal threads is usually more precise and cost effective than using unscrewing cores. The optimum location for external threads is on a parting line of mold members to eliminate the need for unscrewing the mold members that form them. To hold a thread tolerance on a thread diameter, narrow flats—typically .005”—at the parting line are generally specified, as shown in Figure 7. This insures proper mold seal-off, reduces the likelihood of a parting-line vestige, and eliminates problems with flash in the root of the threads, thus reducing mold maintenance.