MIM

What Is MIM?

Process Overview

When to Use MIM

General Guidelines

Technology Comparisons

Materials Range

Materials List

Design Guidelines

Designing for Manufacturability

Uniform Wall Thickness

Thickness Transition

Coring Holes

Draft

Ribs and Webs

Fillets and Radii

Threads

Holes and Slots

Undercuts

Gating

Parting Lines

Decorative Features

Sintering Support

Secondary Operations

Uniform Wall Thickness

Where feasible, walls should be of uniform thickness throughout.Variations in thickness lead to distortion, internal stresses, voids, cracking, and sink marks. In addition, they cause non-uniform shrinkage, interfering with dimensional and tolerance control. Thicknesses in the range 1.3–6.3 mm (0.05–0.25 in.) are preferred, but exceptions in both directions are possible.

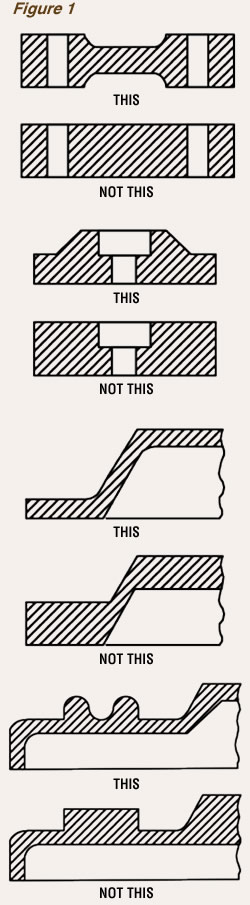

Figure 1 shows several common ways to modify a form to achieve more uniform wall thicknesses. Removing material to create uniformity in wall thickness offers the added advantage of saving material; given the high cost of the very fine metal powders used in MIM, this can be a significant economic benefit.